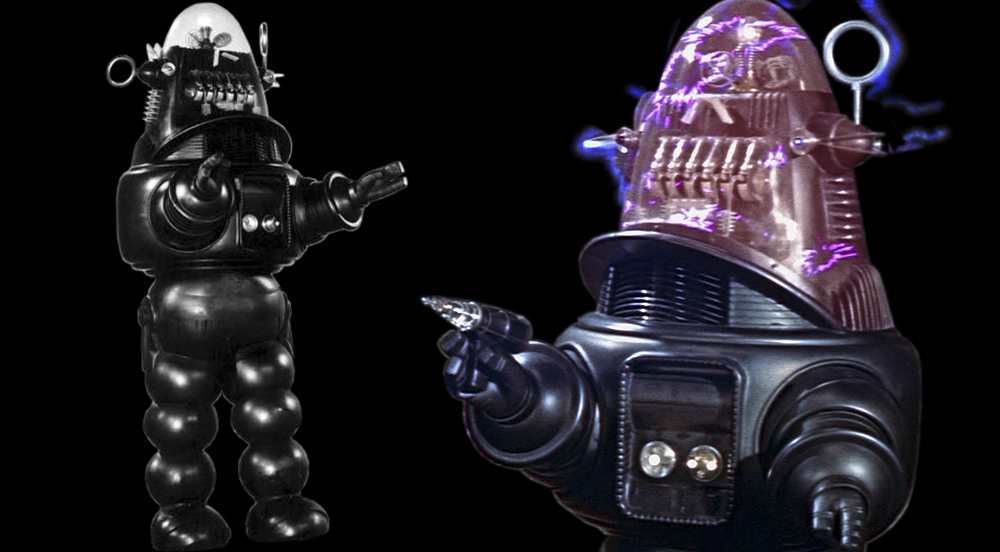

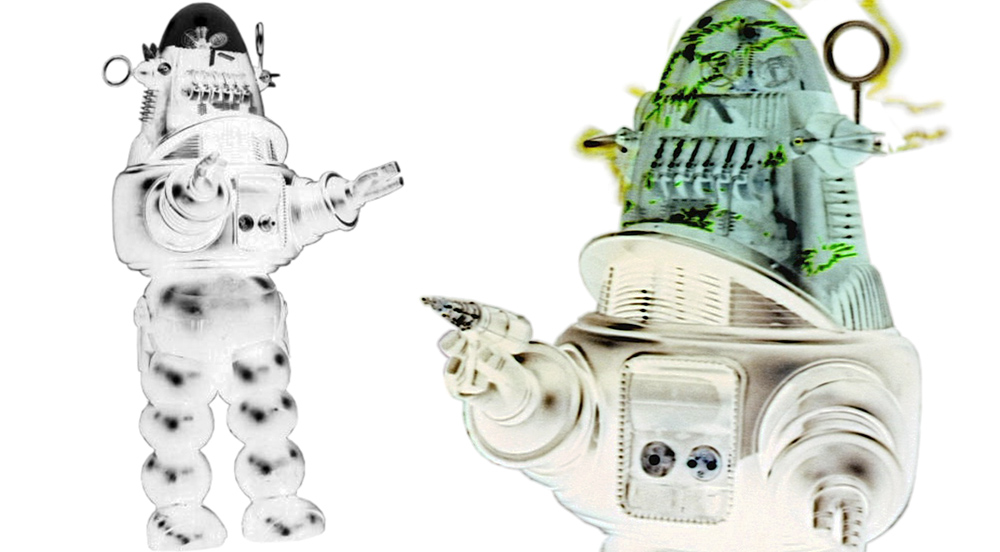

Robby, the Robot

From the 1956 film "Forbidden Planet"

In 1998 I was working long-distance on some commissioned pieces for a prop and model shop based in Orlando, FL. Based on that work, when I arrived in Orlando to work on-site for the final stages, I was asked to assess the work done on a 1:1 scale Robby the Robot sculpture they were making for a client. Their client had plans to mass produce them as a high-end collectible but the process of construction wasn't going as smoothly as they'd hoped.

A duo of freelance sculptors had already done some work on pattern pieces for the body, and I was asked to evaluate their work. I've been obsessed with Robby since I was a kid and am very familiar with the original prop's construction and design details.

The shop had provided the other sculptors with inaccurate blueprints, so the pieces they had done were, therefore, also inaccurate. Unfortunately, they also made some questionable material choices and the parts engineering was all wrong. The upshot was that the project was not only taking much longer to do, but it was also costing far more in material and labor than it should have.

I inspected everything that had already been sculpted, the reference materials and production methods, and gave the shop owners my assessment and suggestions for improvements. Ultimately, they asked me to take over supervising the project and to oversee the changes, but unfortunately, with some very frustrating limitations...

Corrections and Reconstruction

The original sculptors left the project, so one of the shop's owners, Byron Salisbury, and I took on the task of re-working the pattern pieces they had already made to make them as accurate as possible. We also had to complete all of the components and details that hadn't yet been done.

Reconstruction

The original Gauntlet dome and cylindrical Arm were sculpted out of white beadfoam rather than using existing materials of the same shape! We eventually ended up replacing the Gauntlet dome with the plastic lid from a lettuce storage bowl and replaced the Arm with a large tube, making both symmetrical.

Reconstruction

The Leg had also been sculpted out of white beadfoam and we weren't allowed to discard it either. We coated it with a fiberglass mixture and sanded it smooth. We planned on making the second Leg from a partial casting of the first. Why they didn't use existing spheres is a mystery to me.

Construction

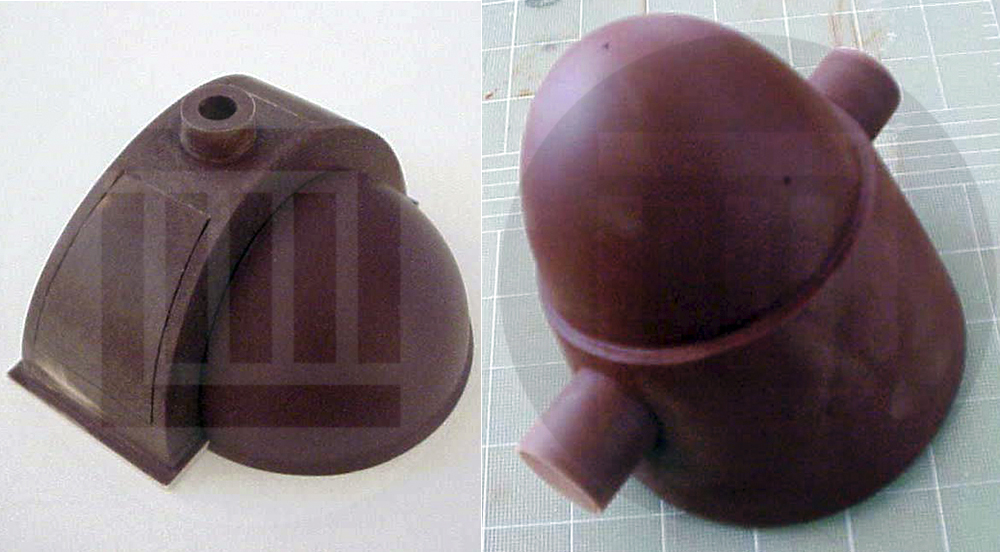

None of the Head details had been made, so I engineered some of the internal head components to be hollow to allow for back-lighting of the resin castings. We fabricated the Ear from parts of a styrofoam egg and a styrofoam cone, sealed it with auto body filler and sanded everything smooth.

Construction

Our plan was to attach some parts, like the six "Sax Valve" Rests, together, then mold it. The resulting castings would have been a single, hollow unit ready for installation and lighting. The streamlined approach would have saved money on production of each Robby statue through the more efficient use of labor and materials.

Project Cancelation

Unfortunately, it was at this stage that the client cancelled the project and went out of business! Because the original, provided parts were so poorly done, we decided not to finish it, even for ourselves. After sitting in storage for years, the molds and pattern parts were finally destroyed.

Final Thoughts

Months of hard work had been done on this project before cancellation. It would have been much quicker and easier if we hadn't been forced to work with the flawed, inaccurate parts that were done before my involvement. In the end, it just proved that sometimes, it is more efficient and economical to scrap something and start over.